How to create an Edge-to-Edge Print with Sublimation

We hope you’re enjoying Pride month so far! To celebrate the occasion, we’re highlighting the benefits of dye sublimation through this joyfully vibrant design.

In this blog we’ll break down what is dye sublimation, how it works and what projects it’s best suited for. Let’s dive in!

What is dye sublimation & how does it work?

The concept of dye sublimation originated in 1950s when chemists discovered that certain dyes could sublimate and bind to synthetic fibres – through a mix of heat and pressure. By the 70s, this technique was introduced to the textile industry and has since grown more popular over the years.

Sublimation printing works by using heat and pressure from the press to transfer the dyes from a special printed paper straight onto the fabric. This chemical process causes the dyes to transition from solid to gas form without passing through a liquid phase, which then embed themselves into the garment material, binding to the synthetic fibres.

First, your design is printed onto a special transfer paper using sublimation inks. We use the SureColor F9400 printer which is especially made for this purpose. The printed paper is then placed onto the carefully pre-pressed fabric. This is done to prevent white streaks which are caused by fabric folds. A heat press applies high temperatures (usually around 400°F) and pressure, which causes the dye molecules to embed themselves directly onto the polyester fibers, creating a permanent, vibrant image that is resistant to fading and peeling.

What do I need to know to achieve best results?

- The technique requires upmost precision to limit creases as any folds will affect the print and be visible on the final product.

- Design requirements: The design printed must include a bleed to ensure full coverage.

- Dye sublimation is most suited to white garments with a high polyester content as the dyes merge with the synthetic fibres of the garment. Choosing to do this technique on a lightly coloured garment would result in a less vibrant colour pay-off, which could achieve a vintage look. However, it’s not possible to sublimate directly onto dark garments as the print won’t be visible.

- To enhance colour saturation & achieve a vibrant result, it’s best to print on fabrics with high polyester content as those fibers bond best with the dyes.

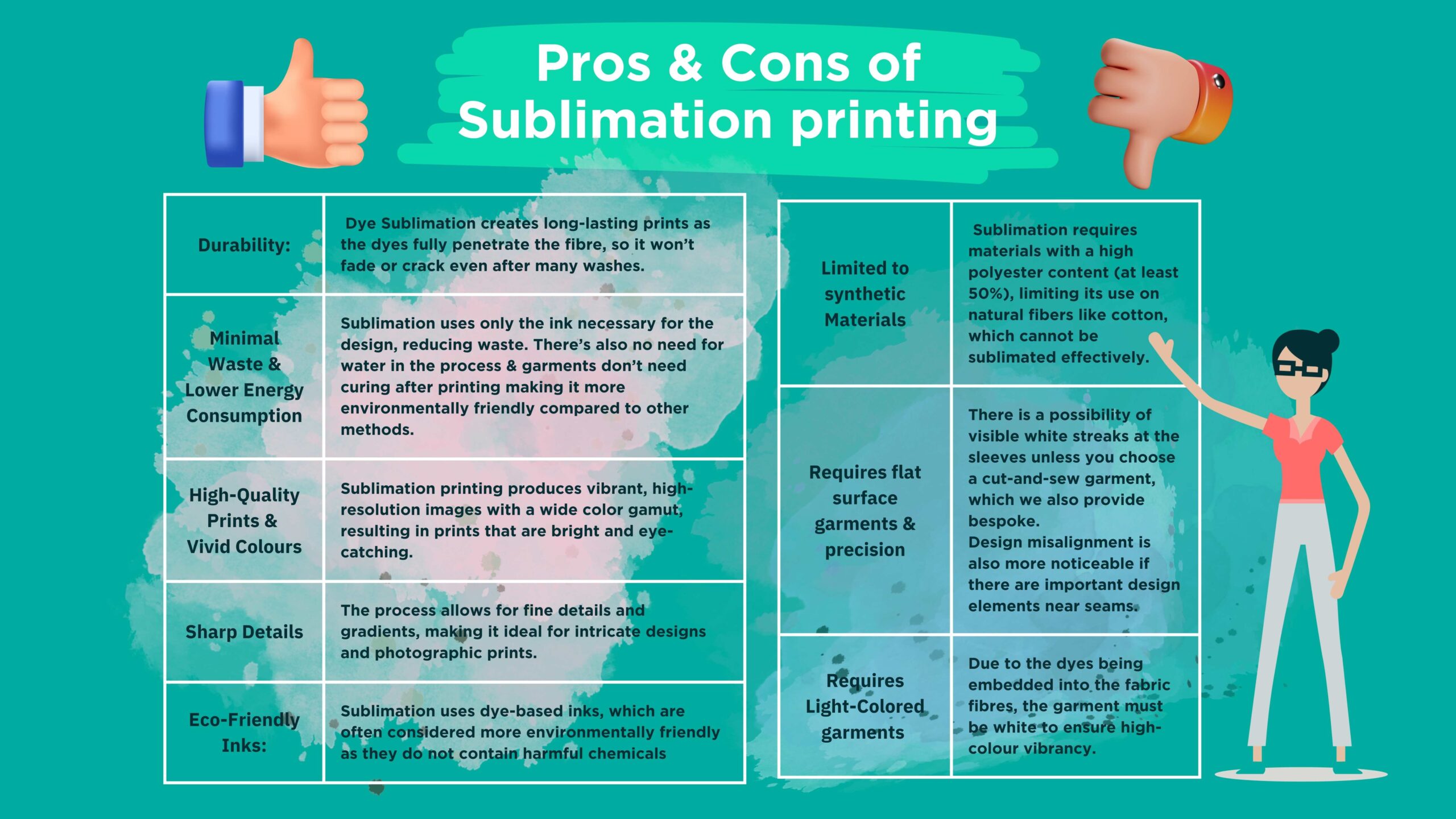

The Pros & Cons of dye sublimation for garment decoration:

The pros outweigh the cons when using dye sublimation to decorate garments. Compared to traditional screen-printing, this method requires fewer resources & consumes less energy to achieve one print, making it perfect for smaller batch orders & intricate designs. Another major perk to this method is its longevity – sublimated designs are more resistant to fading & wear, due to the dye integrating into the fabric fibres.

Additionally, sublimation is unique in its ability to produce full-coverage, edge-to-edge prints that encompass the entire garment, a feature that sets it apart from other printing techniques and which allows for more creative and impactful designs.

So, what type of project is dye sublimation best suited for?

Dye sublimation is ideal for flat surface garments such as sports jerseys, vests, towels, snoods and promotional T-shirts.

This Pride Design was printed onto the infamous Bella & Canvas Unisex EcoMax Tee which is 100% recycled, crafted from a blend of recycled Airlume cotton scraps and recycled PET bottles. This T-shirt is made using pre-dyed cotton, hence removing the need for water in the production process, conserving valuable resources. This is the perfect match in combination with the sublimation process, as it creates a final product which doesn’t involve water from start to finished product!

Is dye sublimation a sustainable decoration method? Well, that depends.

Due to requiring high polyester content, a garment decorated with sublimation printing has a longer lifespan than most. If you’re looking to decorate fewer items, this technique is ideal due to the lower energy consumption required to produce. It is not only cost effective but also generates high quality and durable prints. However, if you’re looking to decorate an organic garment made from 100% natural fibres, you may want to opt for screen-printing with water-based inks or Direct-To-Garment printing as these decoration methods are plastic-free and create a fully biodegradable product.

Whatever you decide – The team at Screenworks is here to support you from start to finish.

Happy printing and stay proud! 🌈